In

modern manufacturing and mass production, automatic spray guns have become

indispensable production tools. From automotive assembly to electronics

coating, food packaging lines to home appliance surface finishing, automatic

spray guns are reshaping traditional coating standards with their stability,

efficiency, and controllability. This article offers a comprehensive analysis

of how automatic spray guns work, selection strategies, application cases,

maintenance practices, and future technology trends, helping you stand out in

today’s fiercely competitive market.

Core

Advantages of Automatic Spray Guns

Compared

to manual spray guns, the biggest strengths of automatic spray guns are

automation and continuous operation. Integrated with production lines, robotic

arms, or automated systems, these spray guns can work uninterrupted for

extended periods, maintaining consistent spray volume and uniformity. This

significantly reduces labor costs and human errors. Modern automatic spray guns

often come equipped with high-precision control systems, allowing adjustments

to spray pressure, flow rate, spray pattern, and movement speed, ensuring

optimal results across various products and process requirements.

How

to Choose the Right Automatic Spray Gun

When selecting an automatic spray gun, consider the following key factors:

- Spray Material: Different coatings (e.g., solvent-based, powder, water-based, adhesives, sealants) require different internal materials, nozzle designs, and atomization technologies.

- Production Needs: High-volume production lines demand durable, high-speed guns, while small to mid-scale production may prioritize versatility and adjustability.

- System Integration: Determine whether the spray gun can seamlessly interface with existing robotic arms, conveyors, or sensing equipment — a critical evaluation point before implementation.

- Energy

Efficiency and Sustainability:

Low-emission, high-transfer-efficiency systems (such as HVLP, LVLP) can

significantly reduce overspray and material waste, complying with environmental

standards and lowering costs.

Automotive

and Industrial Applications

Automotive Industry

Automatic spray guns are widely used for body shell painting, chassis

rustproofing, and interior part coating, achieving high-precision, multi-layer

spraying through multi-axis robotic arms and programmed control.

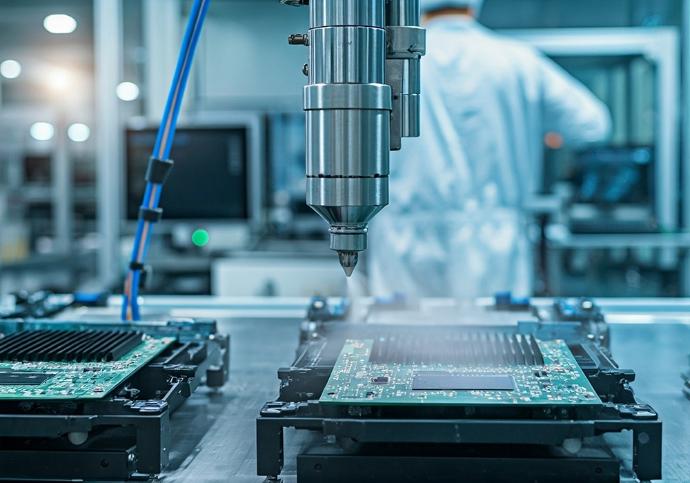

Electronics

Industry

Precision

spraying applies to circuit boards, heat sinks, and component surface

treatments, requiring exceptional uniformity and ultra-thin coatings.

Food

and Packaging

Employed

for protective films, labeling sprays, and packaging coatings, emphasizing

speed and high hygiene standards.

Market

Innovations and Future Trends

With the rise of Industry 4.0 and smart manufacturing, automatic spray guns are entering a new era of digitization and intelligence.

Modern systems now integrate sensors, digital pressure monitoring, flow control, and AI optimization algorithms to enable real-time adjustments, remote monitoring, and predictive maintenance.

Additionally, environmental regulations and sustainability demands are driving the widespread adoption of low-VOC coatings and high-transfer-efficiency spraying technologies, pushing spray gun designs toward greater energy savings and emissions reduction.

Recent hot technologies include:

- Smart Spray Control Systems: Using AI to automatically adjust spray parameters, reducing waste and optimizing quality.

- Collaborative Robot Integration: Enabling flexible, multi-variety, small-batch production and improving manufacturing agility.

- Data-Driven

Optimization:

Leveraging spray process data to continuously refine workflows and product

quality.

Final

Thoughts

Automatic spray guns are not just pieces of equipment — they are comprehensive system solutions that drive productivity and enhance quality.

From selection and implementation to daily maintenance, every step requires thoughtful planning and professional management. Facing growing market challenges and environmental pressures, only by embracing innovation and adopting smart manufacturing can companies secure a competitive edge.

We

hope this article serves as a practical guide and inspiration for your journey

with automatic spray gun applications, helping you build a more efficient,

sustainable coating future.